Sony’s new supply chain will allow high-end cameras to use biomass-based renewable plastics, fundamentally changing the way they are made

Sony has just revised and published its supply chain in a move for more sustainable plastics in high-end tech, including cameras

The best camera deals, reviews, product advice, and unmissable photography news, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Sony has just revamped its supply chain to shift towards more renewable plastics for its high-end audio-visual products, including cameras.

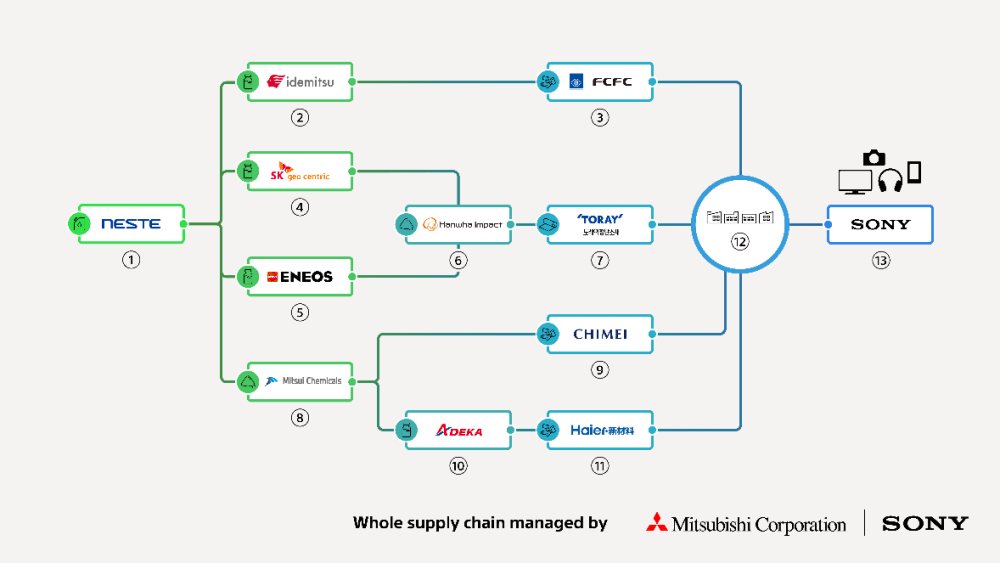

Sony has teamed up with 13 other companies to create a global supply chain across 14 companies and five countries to produce renewable plastics. The joint venture is the first time that an entire supply chain for raw materials to finished products has been visualized in such a way, Sony says.

Sony explained that the plastic components for high-end products can’t be fully replaced with recycled plastics, because those reused materials don’t always meet the standards for flame resistance and optical properties.

Revamping the supply chain will allow Sony to use more renewable plastics that are created with biomass resources or energy created from organic materials. The change will help Sony source more materials that have similar properties to plastics made with fossil-based processes.

The move is also a step towards transparency, publishing where different materials come from, while also expanding the ability to track more greenhouse gas emissions. The change is part of Sony’s goal for “zero environmental impact” by 2050.

“We chose this method because it does not change the quality of the product,” said Sony’s Hisaoki Ohba. “What changes is the feedstock of the materials we use. This fundamentally changes how products are made, which is why the entire supply chain must work together.”

Manufacturing, even when working with recycled materials, has an impact on the environment. But Sony sharing its full supply chain is an unusual move, and hopefully one that could help reduce the tech maker's impact on the environment.

The best camera deals, reviews, product advice, and unmissable photography news, direct to your inbox!

You may also like

Browse the best Sony cameras or the best Sony E-Mount lenses.

With more than a decade of experience writing about cameras and technology, Hillary K. Grigonis leads the US coverage for Digital Camera World. Her work has appeared in Business Insider, Digital Trends, Pocket-lint, Rangefinder, The Phoblographer, and more. Her wedding and portrait photography favors a journalistic style. She’s a former Nikon shooter and a current Fujifilm user, but has tested a wide range of cameras and lenses across multiple brands. Hillary is also a licensed drone pilot.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.