Your camera sensor is mostly blind, but that could be about to change

New start-up Eyeo has developed sensor tech that could radically improve image quality, while still being compatible with existing sensor construction

The best camera deals, reviews, product advice, and unmissable photography news, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Dutch start-up Eyeo has secured €15 million in seed funding to develop new image sensor technology with the goal of tripling a sensor's light sensitivity. The new color-splitting photonics innovation is said to "unlocks picture quality, color accuracy, resolution, and cost efficiency, which was never before possible".

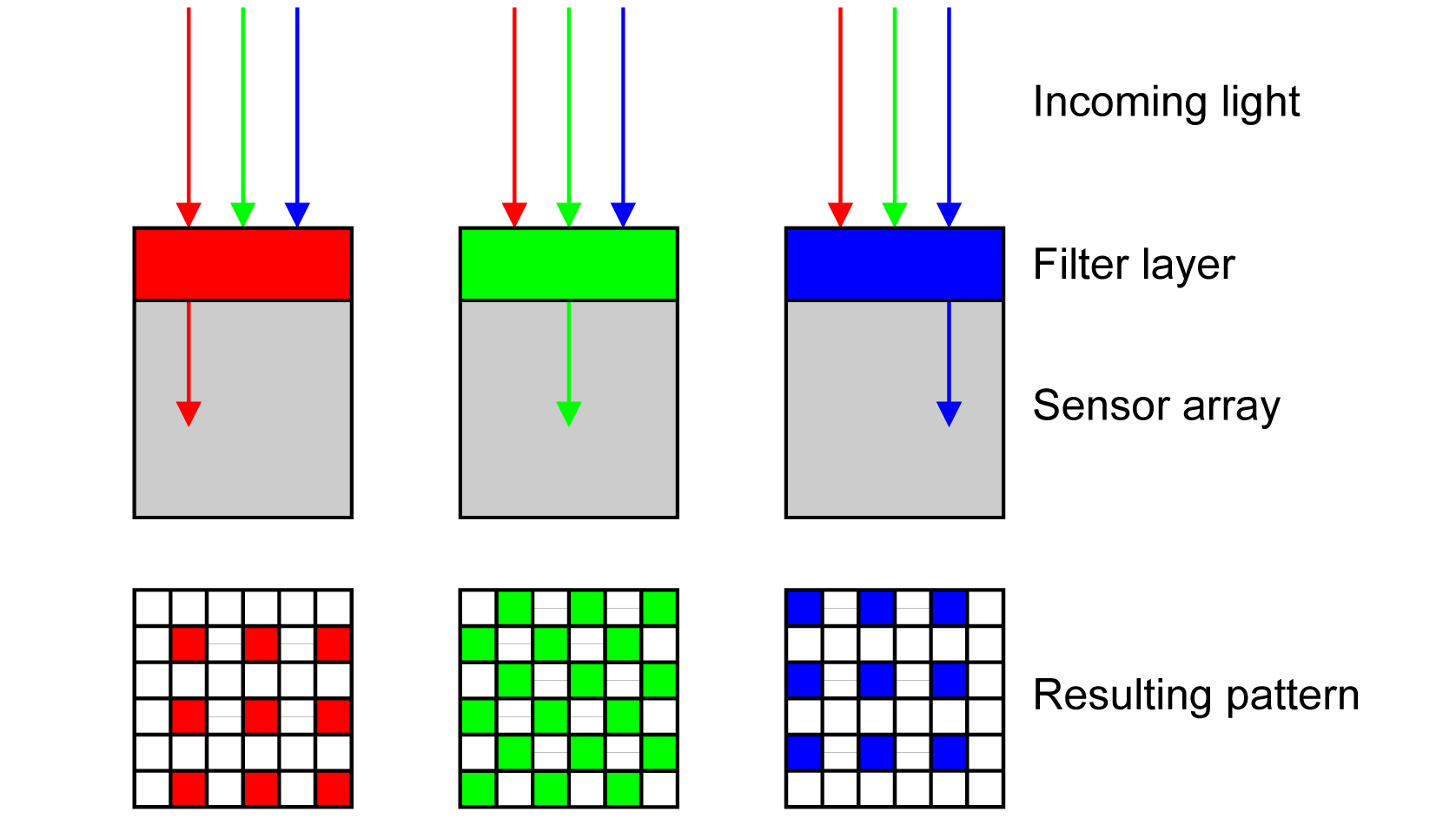

For decades color image sensors have almost always used a Bayer color filter array, filtering incoming light into red, green and blue wavelengths which are then captured by corresponding photosites on the surface of the image sensor. Traditionally a sensor has been divided into 50% green, 25% red, and 25% blue photosites (RGGB), though variations of this have been introduced over the years.

While Bayer filter technology is necessary to enable an image sensor to capture color, it's not without drawbacks. The primary compromise being that each sensor photosite only ever receives a fraction of the light that enters the color filter layer, as at least 50% will be blocked due to it being the wrong color wavelength. This then restricts a sensor's dynamic range and makes it more prone to generating image noise in low light conditions, while the demosaicing algorithms needed to interpolate the raw red, green and blue color data into a full color spectrum will inevitably blur the final digital image to some extent, limiting the amount of fine detail that can be resolved.

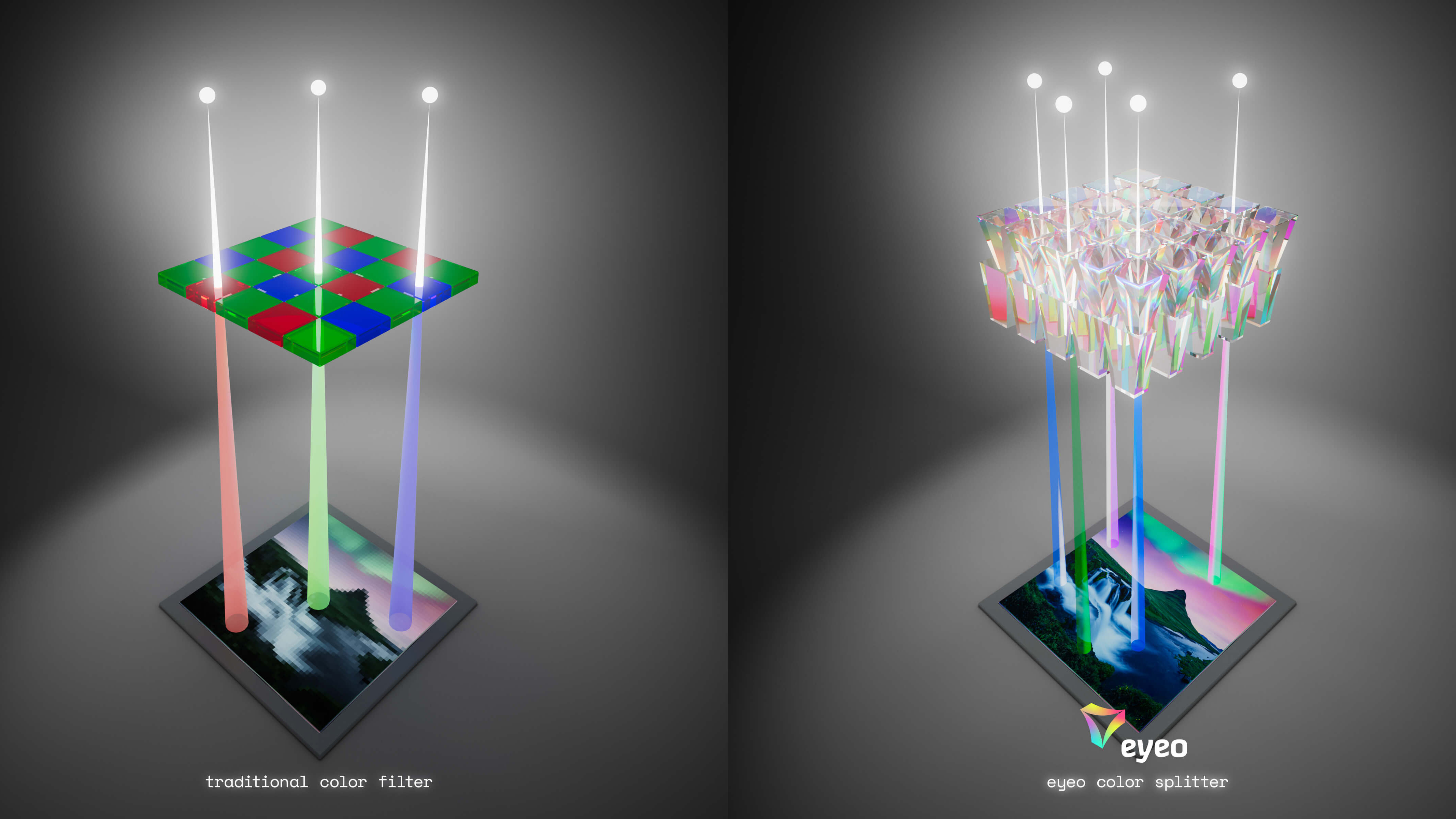

These limitations have long been known, with attempts already made to address them. The most recognizable of these is likely the Foveon X3 sensor, now synonymous with Sigma, which uses a fundamentally different sensor construction that does away with the Bayer filter to drastically increase light transmission. Eyeo's approach, though sharing the same goal as Foveon X3, utilizes traditional CMOS sensor construction, only changing the way in which light is directed to the sensor photosites.

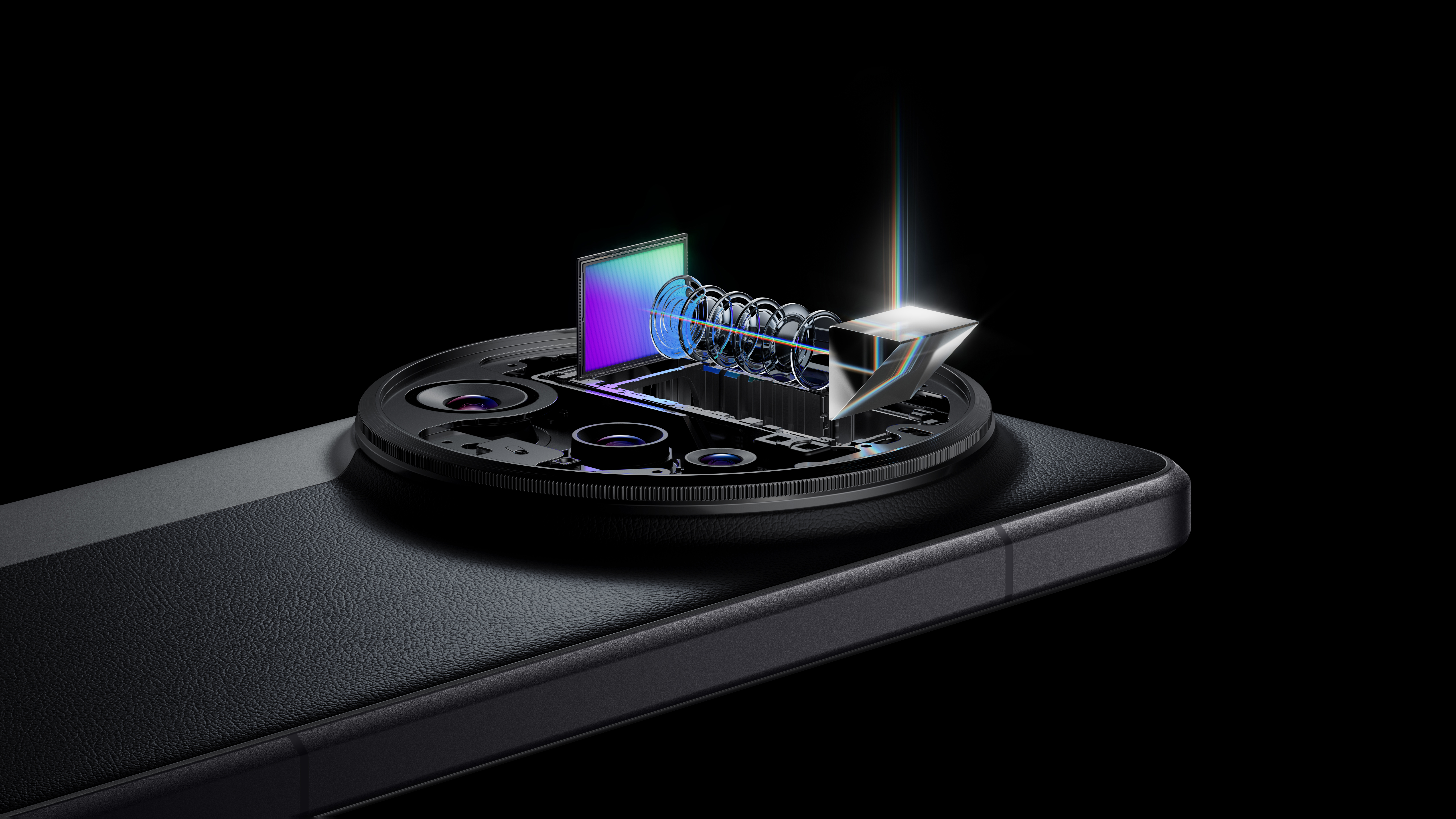

Rather than filtering incoming light (and therefore blocking a large percentage of it), Eyeo's technology guides light to photosites via vertical waveguides, or to use their full name: 'wafer-level-integrated vertical-waveguide sub-diffraction-limited color splitters'. The system implements stacked vertical waveguides to capture full-spectrum white light, guiding each color wavelength to a different photosite. The guides are tuned to direct light based on the average sensitivity of human eye color sensing cones, though they can also be tuned to other spectral ranges, including UV, depending on the sensor's application. By only altering the color-separating layer of the image sensor, Eyeo claims the rest of the CMOS sensor and its electronics can remain unchanged. The company also states that it has already formed partnerships with major image sensor foundries, with this latest seed funding being used to develop a product which could be mass-manufactured.

Ditching the conventional color filter array has the potential to drastically increase light transmission, resulting in noticeably improved image quality without increasing a sensor's physical size. But it also means image sensors can conceivably be shrunk smaller while still maintaining acceptable output quality. That's great news for space-sensitive devices like smartphones and security cameras. The new tech also enables sensor sizes to be reduced without lowering megapixel counts. The use of a Bayer filter keeps pixel sizes to a minimum of 0.5-microns, as going smaller can result in image degradation due to optical diffraction. Removing the color filter and replacing it with vertical waveguides has the potential to allow sensor manufacturers to reduce the size of individual pixels below this current limit. As for when we might see this new technology developed into a consumer product, Eyeo states that "the first evaluation kits are expected to be available for selected customers within the next two years." Watch this space...

The best camera deals, reviews, product advice, and unmissable photography news, direct to your inbox!

Ben is the Imaging Labs manager, responsible for all the testing on Digital Camera World and across the entire photography portfolio at Future. Whether he's in the lab testing the sharpness of new lenses, the resolution of the latest image sensors, the zoom range of monster bridge cameras or even the latest camera phones, Ben is our go-to guy for technical insight. He's also the team's man-at-arms when it comes to camera bags, filters, memory cards, and all manner of camera accessories – his lab is a bit like the Batcave of photography! With years of experience trialling and testing kit, he's a human encyclopedia of benchmarks when it comes to recommending the best buys.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.